1. Objective

This Procedure gives effect to GMW’s Safety & Wellbeing Policy. It establishes the requirements for the management of the risk of falls from height at Goulburn-Murray Water (GMW) workplaces and sites. In particular it:

- Sets out the requirements and procedures for the protection of people undertaking work that presents a risk of falling from more than 2 metres or being struck by falling objects that is reasonably likely to cause injury and or property damage

- Details the risk assessment process and compliance requirements to eliminate or minimise potential fatalities, injuries and incidents arising from risks related to falls

2. Scope

This procedure applies to all GMW employees, contractors, consultants, visitors and labour hire on GMW controlled worksites. It outlines the requirements to prevent or manage the risk of a fall that may result in an injury.

- The term “worker” will be used to describe all GMW employees, contractors, consultants and labour hire

3. Procedure

GMW will take action to manage all GMW assets and tasks to eliminate the risk of falls. If that is not possible, GMW will minimise the risks so far as is reasonably practicable.

For the purpose of this procedure, asset refers to all plant, components, equipment, structures, infrastructure, formations (e.g. rock walls, embankments), and trees.

To manage the risk of a fall at GMW controlled workplaces and assets, GMW will:

- Complete a risk assessment, which identify and assess the risk for all locations and tasks that could cause injury due to a fall

- Develop a safe System of Work

- Supply and maintain suitable plant and equipment for workers to reduce the likelihood of a fall

- Train workers in the safe use of equipment and plant relevant to their tasks

- Educate workers in the risks and controls required for managing falls

- Develop and test emergency response, rescue and first aid plans.

A risk assessment must be conducted prior to undertaking all working at heights activities and documented as a Safe Work Method Statement.

Workers and other affected stakeholders (e.g. land owners) shall be consulted during the risk assessment process.

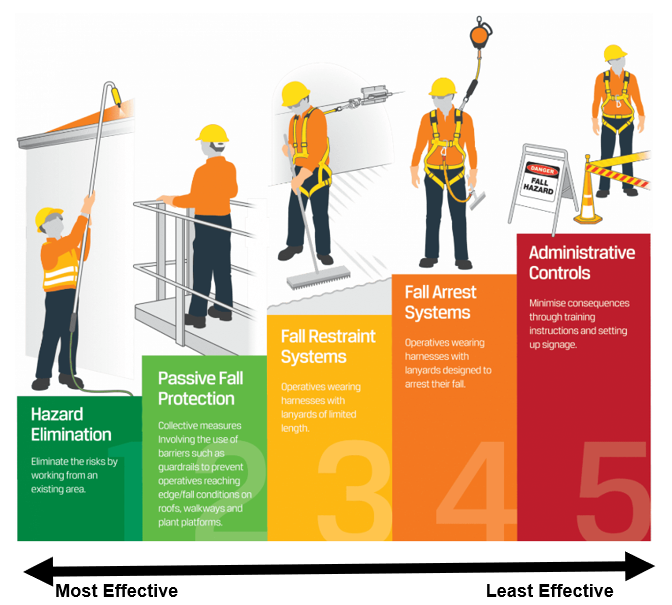

In developing a safe system of work, the hierarchy of controls for managing the risk must be followed, with preference given to higher order controls.

See Associated documents for further control information:

- Risk of Falls Sub-Procedure: Elevating Work Platforms

- Risk of Falls Sub-Procedure: Ladders

- Risk of Falls Sub-Procedure: Scaffolding

- Risk of Falls Sub-Procedure: Man Cages and Work Boxes

- Risk of Falls Sub-Procedure: Fall Arrest and Fall Restraint

Purchased and rented equipment used to manage the risk of falls is to be inspected. When renting equipment the following is required to be supplied by the hire company:

- recent Inspection paper works (this includes testing of height limiters where fitted)

- maintenance schedule and history

- pre-start checklists

If purchasing equipment, purchaser is to ensure that it is manufactured to Australian Standards, and that the item is placed into Maximo and a maintenance schedule is assigned to the piece of equipment.

All work at heights must have plans in place for the emergency response, first aid and rescue of workers who are at risk of a fall.

Emergency equipment must be:

- inspected prior to use (all PPE)

- checked for serviceability prior to job commencing

- consistent with the requirements of the plan

- readily available

- maintained and used in accordance with manufacturer’s instructions and

- reviewed by all workers involved in the task.

Suspension trauma occurs when a worker is suspended in fall arrest equipment for a period of time and can take effect in less than five minutes. Measures must be taken to prevent suspension trauma in the event of a worker falling and being suspended in a harness. Required controls include:

- workers never work alone when using a harness as fall protection

- a rescue plan that can be implemented to ensure the time a worker spends in suspension after a fall is limited (when a suspension is longer than five minutes, foothold straps or a way of alleviating the pressure of the harness leg straps must be provided).

Workers who conduct work at heights must be trained in the task or tasks applicable to their role. Workers working at heights of 2 metres or above are required to be externally trained to meet the requirements of Working Safely at Heights.

Refresher training for all personnel is required and intervals must not exceed two years.

Applicable documentation and records related to the management of falls must be kept in the Electronic Document Management System (Objective) or the Learning Management System as applicable.

This requirement applies to the following documents, where applicable:

- associated safety documents, risk assessments, SWMS

- Working at Heights training and competency records

- registers, inspection data and maintenance records, including NATA certificates for all working at heights safety equipment and/or

- inspection and/or audit results and a record of the subsequent actions required.

4. Responsibilities

| Responsibility |

Who |

| Approval |

General Manager People, Culture & Safety |

| Ownership and implementation |

Manager, Safety Wellbeing and Environment |

Executive and Senior Leadership Team is to:

- Executive and Senior Management (Managing Director, Executive and Senior Leadership teams) are responsible for the following:

- overseeing and ensuring the implementation of the requirements of this procedure and related procedures within their respective functional areas and

- ensuring adequate resources are available to enable the effective implementation of this procedure.

Managers and nominated Supervisors ensure that:

Managers in all operational areas and GMW worksites shall ensure that the risks of falls are minimised through the following controls:

- ensuring that the requirements of this procedure and related procedures are followed in all areas of responsibility

- communicating the requirements of this procedure to their respective areas of responsibility

- manage the requirements for maintenance of equipment relating to managing the risk of falls e.g. harnesses

- establishing a training and competency program in accordance with this procedure

- ensuring that all required work area / equipment inspections are completed thoroughly by suitably trained and competent persons, in a timely manner

- ensuring records and registers of equipment and inspections are held on site and within the Learning Management System

- providing suitable equipment and tools for managing the risks of falls to GMW personnel, contractors and visitors

- providing employees, contractors and visitors with fit for purpose personal protective equipment

- scheduling and coordinating the inspection and maintenance of equipment related to managing falls e.g. safety harnesses, anchorage points.

Supervisors, Team Leaders and Person In Control of Worksite in all operational areas and GMW worksites are responsible for ensuring that the following is undertaken to minimise the risk of falls:

- identify through the risk assessment process tasks where there is a potential risk of falls can occur; This must occur through consultation with the workers performing the tasks

- addressing the risks associated with falls from heights in site inductions

- ensuring all workers are familiarised with the relevant parts of this procedure

- ensuring that emergency rescue plans are in place for all tasks where there is a risk of a fall

- ensuring the tasks address by this procedure are carried out under competent supervision

- documenting and retaining records of equipment inspections both on site and within Maximo

- ensuring only permit trained and competent people carry out tasks where there is a risk of a fall

- educating workers in the risk of falls

- ensuring records and registers of equipment and inspections are held on site and within Maximo.

Workers must ensure that they:

- follow the requirements of this procedure in their respective work areas;

- report all onsite hazards in IRIS

- are active in the identification, reporting and management of fall hazards and related controls in their work area(s)

- carry with them evidence that they have completed the appropriate working at heights training when involved in work at heights tasks and

- seek advice from supervisor regarding the context of risk controls being implemented for the workplace task.

Contractors must ensure that:

- at all times when performing work on a GMW site or for/on behalf of GMW, contractors (unless Principal Contractor) must meet and comply with GMW management requirements detailed in this and related procedures. This includes:

- providing adequate resources to ensure implementation of the requirements of this procedure in a timely and effective manner in all areas where work is undertaken

- complying with this procedure and all relevant legislation, codes of practice, standards and licensing requirements that apply to their respective scope of work and

- reporting all incidents to the GMW Project Manager or GMW Contact

GMW Safety Team ensure that:

- the establishment, review and continual improvement of management systems, arrangements and procedures related to managing the risk of falls

- the provision of advice to assist in the active management and resolution of identified risks of falls in accordance with GMW SMS and relevant legislative requirements.

Visitors must:

- Complete a visitors induction and be accompanied at all times when on GMW sites. Whilst on a GMW site, all visitors shall ensure that they follow the site-specific risk of falls management requirements.

5. Definitions

Administrative Controls: Systems of work or work procedures which eliminate or reduce the risk of a fall.

Anchorage: A secure point for attaching a lanyard, lifeline or other component of a travel restraint system or fall-arrest system. Anchorages require specific load and impact capacities for their intended use.

Asset: Asset is the term used to cover all plant, components, equipment, structures, infrastructure, formations (e.g. rock walls, embankments).

Attachment Hardware: Any ring, hook, karabiner, tube nut connector or other connecting device located in such a position that it must sustain by itself the full loading of a fall-arrest.

Competent person: A competent person is defined in regulation 5 to mean a person who has acquired through training, qualification or experience, the knowledge and skills to carry out the task.

Edge Protection System: Edge protection system complying with AS 1657. Includes, guard railing of between 900 mm and 1100 mm high and a toe-board of not less than 100 mm high fitted at sides, edges and openings except at points of access from a stairway or ladder. There shall be no opening of more than 450 mm between the guard railing (top rail and mid rail) and toe board and no more than 10 mm between the toe-board and platform deck.

Energy absorber: (or deceleration device) device, used with a fall-arrest harness and lanyard, which reduces the deceleration force imposed when a fall is suddenly arrested.

Fall-Arrest System: An assembly of interconnected components comprising a harness connected to an anchorage point or anchorage system either directly or by means of a lanyard, lanyard assembly or pole strap, and whose purpose is to arrest the fall of a person.

Fall Hazard: A source (i.e. task, object or location) that has the potential to result in a fall injury.

Fall Injury Prevention System: Equipment, material, or a combination of equipment and material that is designed to arrest the fall of a person.

Free Fall: A fall in which the distance a person using a fall-arrest harness system falls vertically before the system starts to take loading is more than 600mm (for details on how to calculate free fall refer to AS1891.4).

Full Body Harness: An assembly of interconnected shoulder and leg straps, with or without a body belt, designed for attachment to a lanyard, pole strap or fall-arrest device for fall-arrest or work positioning purposes.

Handover Certificate: a certificate provided to the worksite once the scaffold is complete and ready for use and includes sign-off that the scaffold has been erected in accordance with the supplier’s documented instructions.

Hierarchy of control: a concept that identifies the different methods of controlling risk in order of effectiveness.

Inertia reel: (also known as a self-retracting lanyard or fall-arrest block) - is a mechanical device that arrests a fall by locking onto a dropline and at the same time allows freedom of movement

Lanyard: A line used, usually as part of a lanyard assembly, to connect a harness to an anchor point or static line.

Lanyard Assembly: Consists of a lanyard and Personal Energy Absorber. The lanyard assembly must be as short as practicable and the slack working length no more than 2 metres.

Limited Free Fall: A fall in which the distance a person using a fall-arrest harness system falls vertically before the system starts to take loading is not more than 600mm.

Manager: The Manager who has direct responsibility for the activity being performed or the area the activity is occurring in.

Passive Fall Prevention Device: Material or equipment, or a combination of material and equipment, that is designed for the purpose of preventing a fall, and that, after initial installation, does not require any ongoing adjustment, alteration or operation by any person to ensure the integrity of the device to perform its function.

Pendulum Effect: If a person using an individual fall-arrest system falls, the system may act as a pendulum, and in some situations the user may hit the ground (called ‘swing down’) or swing back onto the building or structure (called ‘swing back’).

Personal Energy Absorber: A device or component used in conjunction with a harness which by design reduces the deceleration force imposed by a suddenly arrested fall.

Restraint system: a system in which a harness attached to one or more lanyards, each attached in turn to a static line or anchorage point, so as to restrict the travelling range and preventing a person from reaching a position from which they could fall.

Risk of a fall: A circumstance that exposes a worker while at work or other person while at or in the vicinity of a workplace, to a risk of a fall that is reasonably likely to cause injury to the worker or other person. This includes circumstances in which the worker or other person is:

- In or on plant or a structure that is at an elevated level;

- In or on plant that is being used to gain access to an elevated level;

- In the vicinity of an opening through which a person could fall;

- In the vicinity of an edge over which a person could fall;

- On or in the vicinity of a surface through which a person could fall; and

- On or near the vicinity of a slippery, sloping or unstable surface that is steep enough so as to present a risk of the worker not being able to arrest their descent should they slip and/or trip. This includes surfaces that are slippery, or unstable.

Scaffold: a temporary structure specifically erected to support access or working platforms.

Scaffolding: the individual components (for example, tubes, couplers or frames and materials) that when assembled form a scaffold.

Scaffold tag (Scaff tag): allow a worker to visually tell if a scaffold is safe to use or not. It contains important information such as: scaffold erection date, the last inspection date, and the duty or load rating of each scaffold platform bay.

Scaffolding work: the erection, alteration or dismantling of a scaffold.

Solid Construction: An area that has a surface capable of supporting any people and material that may be on it and has barriers around its perimeter and any open penetrations to prevent a fall from the area. It must have an even and readily negotiable gradient and a safe means of access and egress.

Static line: a horizontal, near-horizontal or vertical line (ladder fall-arrest device) to which a lanyard may be attached and which is designed to arrest a free fall. Ends of the line is connected to a fixed anchorage point.

Supervisor: Term used for any GMW employee who acts or is appointed as a Supervisor, Coordinator or Team Leader within GMW.

Suspension Trauma: A natural human reaction to being upright and immobile. Blood pools in the legs potentially leading to unconsciousness. If the condition is allowed to develop unchecked, it could be fatal.

Unprotected Edge: Any edge without a handrail / parapet or with a handrail / parapet of less than 900mm in height, at which a fall hazard is present and/or where a gap, void or space of more than 300mm exists and which is not provided with a barrier to prevent a fall.

Work Positioning System: Equipment, other than a temporary work platform that enables a person to be positioned and safely supported at a work location for the duration of the task being undertaken at height. These systems prevent a worker falling over an unprotected edge.

Worker: Employees, contractors, subcontractors, outworkers, apprentices, consultants and trainees, work experience students and volunteers.

If you require a printable version of the Risk of Falls Procedure, please phone GMW on 1800 013 357 and quote the reference A4003981, Version 12.